Manage control types

Control types are the possible packaging of an item that can be controlled in different ways. The control types are set up for each item. Manage control types allows you to define one or more units (item packs). The type of control can also be selected from various options.

You start this from the Stock Controller tab of the item master by pressing the New button in the control types :

| Element / Switch | Function / Description |

|---|---|

| name | The name indicates the control type and is also displayed during the control of the stock. Example: 1 litre bottle |

| unit |

The unit is either pure text information or, for volume units, contains the weight information that represents the volume. Further documentation: Units general |

| number |

The Number field contains information on the relationship between the control type and the base unit. If in our example the base unit is litres, then a 1 litre bottle can be present 1 time in the litre, likewise a 1.5 litre bottle would be present 1.5 times in the base unit. |

| Actual transport unit | The control type to be used for internal postings is the transport unit. Select this setting for each control type of an item. |

| on assembly lists |

You can now create control types that also appear on the assembly lists of the MRP monitor. Several units can be created. For example: beverage cans: basic unit or transport unit is bottleunits for placement lists are pack per 6 pieces, pallet per 24 pieces. If, for example, 32 bottles are required, the printout 32 bottles ( below is the info ) 1 * pallet 24 pieces 1* pack of 6 pieces 2 * bottle. These placement units are sorted according to "quantity" and checked whether a unit can be used ( quantity fits ). At the same time, these units are of course also available for checking and enable differentiated / easier recording of stocks. |

| control type | The type of control defines the type of control, in other words, the means of control. |

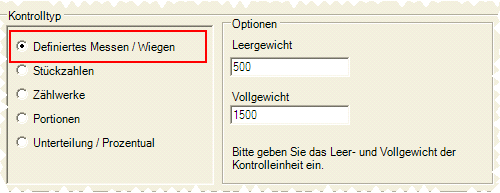

The defined measurement serves to record the stock on the basis of the weight. This enables you to record partial stocks as accurately as possible, which can optionally be recorded with a connected digital scale. Depending on how many of your items have been opened during the inspection, the connected digital scale represents a correspondingly valuable work simplification.

The unladen weight is the weight of the packaging, so that, for an unladen weight of 500 g, a weighted weight of 850 g means that 350 g of goods are present.

The full weight completes the control mode at the top. The item should not be heavier than the full weight, i.e. packaging and goods.

If you have items with different weights in the packaging, then enter the lightest packaging with empty weight and the heaviest packaging including the weight of the goods even with full weight. This distributes the tolerance best to the number of portions contained.

In order for data to be read automatically by the digital scale during the check, you must use a unit that has a g in the Description field. Otherwise, the weight can only be entered manually.

Quantities are control types of items that you can easily count, such as portion bottles.

Quantities are without further options as they are clearly defined.

The control type Registers enables you to calculate and compare stock on the basis of counts. If, for example, you do not connect a coffee machine with our dispensing system interface, you have here a manual control as an alternative.

Choose between a continuous counter and a resetcounter. After booking a check, the reset counter starts from zero again - that means that the device you are reading is also set to zero by you.

Choose Manage Inventory in Warehouse if you want the meter reading to calculate the goods consumption in the warehouse, not in the point of sale. This variant is used, for example, for central beer and spirits tanks.

In the Number of pulses per counter field, you can enter a divisor for such counters that display only pulses and not matching portions or units, which converts the pulses into counter units.

The number of counter progresses is calculated on the basis of the control input and the previous input. In addition, the theoretical consumption from the inventory service is calculated for the area between current and last check. This theoretical consumption is now compared with the meter reading. The quantity determined from this is added to the current theoretical target. This results in a theoretical control quantity. Since this theoretical control quantity does not have to be correct, but the counter reading is correct, it is possible to enter the quantity correctly. The theoretical control quantity (displayed under Base unit) can then be overwritten with the actual quantity detected. However, the counter reading is noted in the check as recorded.

During the first application and even if the number 0 (zero) has been entered, the continuous counter cannot be calculated correctly. Enter 1 (or higher) at the first check to get a start value. At the next control close, this number can be used together with the current input to determine the progress of the meter.

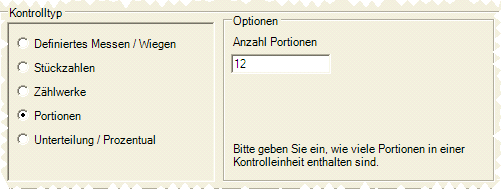

Portions are a "loose alternative" to the other control types and allow you to enter the most estimated portions of the item.

In the Number of portions field, enter how many portions make up an entire base unit.

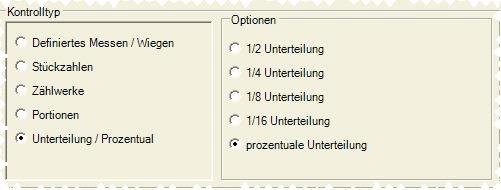

In this area, you can specify control types for percentage entry or in fractions.

If you use percentage subdivision, you can enter a percentage for the check. A subdivision into quarters can then capture up to three quarters, if there are four quarters, you should capture a whole.

Back to the parent page: Basic units and control types